PXV vertical order picker sets new standards

Liebherr Hydraulikbagger GmbH

Sector: Construction machinery

Company: 140 companies across all continents with 49,000 employees (last updated: 2021)

Challenge: Equipment for a new production warehouse with a range of assembly parts consisting of 27,000 items.

Solution: Use of the new STILL PXV vertical order picker (in a field test) with a reach height of 14.5 m to optimise space utilisation.

Further products: Even before the field test of the new PXV, the production warehouse was equipped with warehouse trucks and material handling technology, STILL MX-X very narrow aisle order pickers and STILL EK-X vertical order pickers.

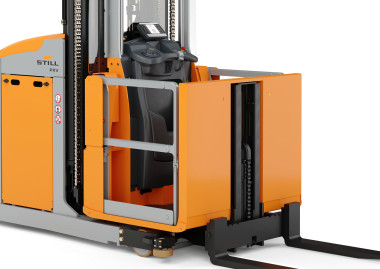

Even the highest shelves are within reach of the new PXV vertical order picker, which has a reach height of 14.5 metres. That is a record high! Alongside this enormous order picking height, other remarkable performance features include high lifting and lowering speeds, and the simultaneous lifting and lowering of both the main and additional lift.

Liebherr-Hydraulikbagger GmbH has put the PXV through its paces. Another particularly impressive feature, apart from the astonishing reach height, is the smooth and continuous lifting and lowering process without any rattling or shaking in the legs. The clear displays and user-friendly control elements in both the lifting and load direction ensure maximum flexibility and extremely high safety standards. The intelligently arranged storage compartments in the spacious operator’s cab, along with the knee and support cushions, ensure the operator instantly feels right at home.

About Liebherr

The Liebherr Group was founded in 1949 in the southern German town of Kirchdorf an der Iller, and is now one of the largest construction machinery manufacturers in the world, with over 140 companies across all continents. In 2021, the Group employed more than 49,000 staff and generated over 11.6 billion euros in consolidated total revenue.

Liebherr-Hydraulikbagger GmbH, based in Kirchdorf an der Iller, develops and manufactures an extensive range of high-quality hydraulic excavators, material handling machines and articulated dump trucks. These powerful machines have made their mark in a wide range of applications across many industrial sectors, and are used around the world. In 2021, the company, which has around 1900 employees, generated approximately 870 million euros in revenue.

Larger production warehouse

Liebherr-Hydraulikbagger GmbH’s reaction to increasing demand came in the form of the two-phase construction of a larger production warehouse in 2019 and 2021. In its role as general contractor, well-known Hamburg intralogistics equipment company STILL planned, delivered and installed warehouse trucks and material handling technology as well as industrial trucks. With 27,000 items, the range of assembly parts is simply vast. Large and heavy assembly parts are housed in pallet stores in the 22-metre‐high warehouse. Every day, a fleet of eleven MX‐X very narrow aisle order pickers is used to pick production orders from pallets or grid boxes. Long and bulky assembly parts are housed separately in a wide‐aisle warehouse, where the MX‐X also helps to assemble production orders onto special pallets via an overlength swivel traverse fork. Jochen Rudolf summarises, “with a maximum order picking height of 17.4 metres and a load capacity of 30 tonnes per shelving bay, we have reached the limits of what is possible in our pallet stores.”

Aim high: forklift-managed shelving warehouse

The storage system in the production warehouse is equally distributed to ensure balanced capacity utilisation. Over two shifts, 30 employees pick orders according to the ABC and FIFO principles. Every day, that equates to the retrieval of 3000 items and the storage of 2000 items.

Smaller assembly parts are housed in SLC containers within a shelving system, located in another vast warehouse with twelve-metre-high shelves and 40 levels. Here, assembly orders are picked using six EK‐X vertical order pickers. When it comes to assembling production orders, the inductively guided trucks use assistance systems from STILL to safely find their way.

Order pickers reach record heights

The PXV vertical order picker is the successor to the EK‐X. Whether it is being put to use in the narrow- or wide-aisle warehouses of industrial companies, logistics service providers or in the logistics centres of large retailers, this flexible and reliable new truck from STILL was developed for use in a wide range of sectors and applications.

It has already impressed Jochen Rudolf during a field test, and he says, “the exceptional reach height now allows us to pick orders at chest height, even from the highest shelves. This means that dangerous ‘overhead lifting’ is finally a thing of the past.” Alexander Claus, Product Manager for very narrow aisle trucks at STILL, adds, “the new order picker has a reach height of 14.5 metres, meaning it can reach even the highest shelves. This enables an unbeatable use of space. Our trucks allow warehouses to expand further upwards, without the need for additional sealed floor areas.”

Workflows with improved performance and safety

Thanks to state‐of‐the‐art proportional valve technology, the lifting speed of the PXV can be continuously controlled. Smooth mast transitions not only ensure comfortable working but also impressive goods handling. Cengiz Beckel, Team Leader at the production warehouse, agrees: “The now continuous mast transition journeys mean that vibrations and oscillations no longer occur. In the PXV without free lift, a clear view through the mast always ensures safe journeys in the drive direction.” In the PXV with free lift, both free lift cylinders – which are in an offset position in relation to the mast profile – also provide optimal visibility through the mast in the drive direction.

The Team Leader adds that controlling the test truck is extremely flexible due to the integrated load and lift operation. There is no longer any need to even enter a key combination to change the mode of operation. Instead, just waving a hand close to a sensor will automatically switch the control elements. This means that the highest safety standards are always guaranteed during order picking.

Efficient and fast goods handling is achieved through the possibility of the two‐sided operation. STILL Easy Touch makes it possible to simultaneously lower both the main lift and the additional lift at the touch of a button during order picking. The smart assistance systems from STILL also provide a higher throughput of goods. Jochen Rudolf confirms that, “the assistance systems make it possible to reach the right bay quickly. To allow us to do this, STILL has specifically programmed the 40 levels of our shelving warehouse into the iGo pilot navigation.”

Greater comfort, improved ergonomics and more space

The intuitive and ergonomic control panel with steering wheel or steering knob is adapted to individual requirements and makes all functions easy to operate. The intelligent storage concept within the spacious cab provides plenty of space for a data terminal, scanner, printer and other equipment. Even rounded cab elements have been designed with corners in the new PXV, to allow them to be used as possible storage spaces for small containers. There is also improved protection against getting fingers trapped when lifting the tilting barrier.

Numerous details, such as the ergonomic driver’s seat with optional tilting technology, the proportional seat and foot plate adjustment, the ability to adjust all control elements to the driver’s ergonomic requirements and the panoramic mirror, ensure optimum visibility of the fork tips.

Knee and support cushions create a healthier and more comfortable workstation for the operator. The lateral tilting barriers on the operator‘s cab enable easy access to goods, no matter how far back they are. The spacious shock-protected stand-on platform with integrated presence switch provides optimum user comfort.

Fast charging with direct charging access ensures high availability of the PXV. Easy handling of the plug connector makes the charging process much easier.

Summary

With maximum reach heights of 14.5 metres, the new PXV vertical order picker from STILL handles the growing trend toward higher storage areas. The new truck offers improved handling performance and enables a particularly high level of warehouse and floorspace utilisation. Thanks to the modular truck concept, the PXV can be individually configured for use in a wide variety of applications. The truck is impressive in terms of its user-friendliness, ergonomics and safety. Smart assistance systems such as iGo pilot and OptiSpeed provide fast, safe and smart access to the 40 shelves, at the highest possible driving speed without jeopardising safety. It also offers an excellent field of vision in the load and drive direction, plus a spacious, shock‐absorbing operator‘s cab with tilting barriers for easy access to goods. Additional assistance systems for even greater safety and efficiency plus numerous equipment variants can also be selected individually and make the PXV the perfect, tailor‐made companion for every warehouse.